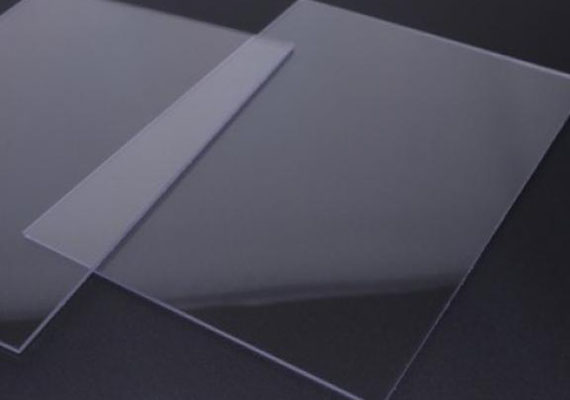

IPolycarbonate (PC) yenziwa ibe licwecwe lenkqubo ye-extrusion. Kwinkqubo yokukhutshwa, i-polycarbonate iqhutywa ngokuqhubekayo kwisikere kummandla wobushushu obuphezulu kunye noxinzelelo apho inyibilike kwaye idityaniswe, kwaye ekugqibeleni inyanzelwe ngohlobo lokufa. I-PC inokukhutshelwa kubukhulu obahlukeneyo: 0.25mm, 0.5mm, 0.7mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm kunye 2.0mm. Ubukhulu obuqhelekileyo busetyenziswa yi-0.5mm, 0.7mm, 0.8mm kunye ne-1.0mm.

I-PC inokuxutywa nembala eyahlukileyo ukuze ibonakalise, ifluorescent, isiphumo sokukhanya kunye neselubala.

Iscrew extruder sinokusetyenziselwa ubume obahlukeneyo ukwenza iphepha lePC.

Ukudityaniswa kwePC / PMMA. Iifilimu okanye amaphepha aneendlela ezimbini okanye ngaphezulu ezahlukeneyo zeepolym zinokuveliswa ngokudibanisa imilambo etyhidiweyo. Le nkqubo inokusetyenziselwa ukudibanisa izinto ukubonelela ngokudibanisa iipropathi ezingenakufunyanwa kwipolymer enye.

I-PC yokwenza i-vacuum inokubonelela ngokhuseleko njengekhakhayi likhusela ingqondo.

I-PC yokwenza i-vacuum inokushenxisa umaleko ukwenza umsebenzi we-MIPS ukuze ulawule amandla ejikelezayo.

I-Thermoforming yinkqubo eyaziwayo yokwenziwa kwesigcina-ntloko, ebeka iphepha elinombala wesilika kwisikwere se-oveni ukulungiselela ubushushu, ibeka i-polycarbonate kumatshini wokucoca, iphepha lifudunyezwa kubushushu obunokubumbeka, obenziwe ngendlela ethile ekubunjeni, kwiimveliso ezahlukeneyo kwaye ukuphakama kunokubangela ukolulwa okwahlukileyo ngexesha lokuyila, i-vacuum encinci yePC yenze umngcipheko wokuba umbala uphele okanye ukunciphisa amandla kwisigcina-ntloko, ke kubalulekile ukuhlalutya nokukhetha ubukhulu beephepha ze-polycarbonate ezinxulumene nomgangatho wesigcina-ntloko kunye novavanyo olunefuthe. kwaye ndiyicwangcisile ukwenza imveliso enokusebenziseka.

Ngaphambi kokuba kwenziwe inkqubo yokwenza into, sisebenzisa umaleko wokukhusela ifilimu kwiphepha le-polycarbonate emva kokukhutshwa, ifilimu ikhusela iPolycarbonate ekukrwemeni ngexesha le-EPS ekubunjweni, kwaye isuse ifilimu yokukhusela xa indibano yokugqibela yesigcina-ntloko ekugqibeleni.

I-PCMA edibeneyo yePC

Imibala yePC ebonakalayo

I-Mirror Optical PC

PC enombhalo

I-PC yeFluorescent